“Making syrup required a lot of hard work from the planting through the pouring up of the molasses. I remember the cutting of the seed heads, stripping the fodder, cutting the stalks and hauling them to the mill, these were all part of my job then my Dad ground the stalks through the mill with the juice flowing into a #10 tub with a cheese cloth covering to keep any trash and or Yellow Jackets out of the juice.

We had a spigot soldered on the tub with a hose where we could control the flow of the juice to another tub down next to the river where the boiler was located. My Grandpa was the cooker and we used a boiler instead of an evaporator since you could better control the cooking, an evaporator runs the juice through to fast and leaves a lot of uncooked juice which will turn to sugar and not keep like slow cooked syrup will.

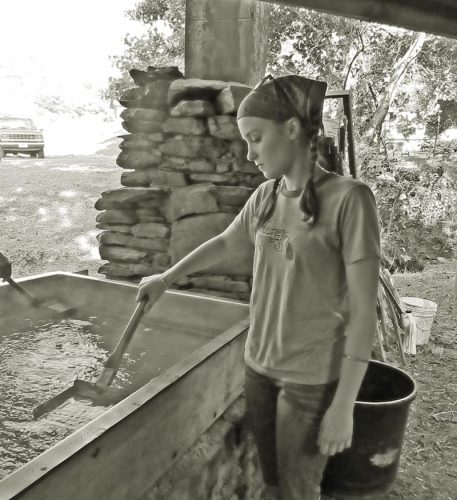

Grandpa used the tub where the juice ran to from the tub at the mill to fill the boiler and add juice if needed during the cooking. Grandpa had a homemade skimmer like Chitter is using in the photo above and a wooden scraper to keep the syrup from sticking to the copper bottom of the boiler which we had built with a medium thick sheet of copper.

We used a horse to power the mill, the sweep pole which attached to a metal plate that sat down on top of one of the mill rollers which had teeth on the top which meshed with matching teeth on the other roller. This sweep pole had a smaller pole attached to a hole in the larger end of the sweep at a ninety degree configuration, the horse’s reins was fastened to the smaller end of the smaller pole and the harness attached to a single tree which was attached to the larger end of the sweep.

When Grandpa decided the syrup was done it had a lighter bronze color since with the boiler you could cook all the green out without scorching the syrup. The next step required four people to lift the boiler and pour the syrup in five gallon cans which we would transfer to what ever size jar or jug a person wished to purchase.

We always kept the skimmings and mixed them with ground corn and fodder to feed the cattle. Though this involved a lot of labor intensive work and drew Yellow Jackets from several counties I enjoyed it since this was the only time I got to miss school and we always wrapped potatoes in the hot coals under the boiler to enjoy when ever you wanted one, during the course of the day this called for several potatoes, I still love potatoes baked in hot coals with freshly churned butter.

These were hard times but good times. I still have our mill but I haven’t made syrup in years, We usually made between three hundred to three hundred and fifty gallons of syrup a year. I talked to a couple from Franklin a couple of months ago who commented that they wished we still made molasses as it was the best they ever had, it made me feel good that all our hard work was appreciated.”

—Bill Burnett – September 2019

Last night’s video: Mountain Path 4

Subscribe for FREE and get a daily dose of Appalachia in your inbox

My home County in E. KY had a wonderful Sorghum Festival each year until COVID hit. There was a huge tent over most of Main Street, where homemade quilts and many other beautiful crafts were sold. A “Cane mill” in the city park was operated with either a horse or mule constantly going around in a circle, as a man “fed” stalks of cane into the grinder. This squeezed the sweet juice through a line or trough and it dripped into a huge rectangular pan about ten feet long. There was a wood fire underneath in order to boil the juice. Someone was constantly stirring it with a long handle tool that looked like a window squeegee. There were maze-like sections and each space was stirred until it reached the end, where it dripped into cans. It was boiling hot and the sweet aroma was wonderful. I never heard it called anything except Sorghum.

Just a small comment to clarify. Actually Molasses is a by-product of the sugar making process. That is why if you buy molasses at the grocery, you may be disappointed. What we are talking about and what goes so good on hot biscuits is sorghum syrup or “surp”. They sell it at the Farmer’s Co-op and a group makes and sells it in Muddy Pond, Tennessee

As a young child my dad planted sugar cane and in the fall all of the neighbors came over to make the syrup. A neighbor brought his horse to operate the mill to press the juice out of the cane stalks. We had a fire pit and the pan to boil the juice to cook into syrup. At the end of the day each neighbor got a share of the syrup to take home.

Those were good days. We would put a dipper under the flowing cane juice and drink a little. The syrup kettle we used to boil the syrup in was round cast iron. I have an 80 gallon one in my yard….used as a garden pond. The bullfrog that lives there seems to like it.

We never called it molasses. We called it “sorghum surp” (that’s syrup to the overly educated). We fed molasses to the chickens. Horses and cow like it too but we didn’t mix it in their feed. They got store bought sweet feed with molasses already mixed in. Sorghum surp is much better than molasses if it is cooked right. For my taste it has to be cooked until all the green tint is gone otherwise it tastes grassy.

If anyone is interested in my recollections of surp making please read this comment I made on another of Tipper’s posts. https://blindpigandtheacorn.com/appalachia-through-my-eyes-helping-skim-the-syrup/

Bill was a library of information about Western North Carolina. I encouraged him to write down some of his knowledge and experiences. As far as I know he didn’t! Only those he shared with you, Tipper. He thought he couldn’t write well enough.

We did collaborate in a massive family tree with the names of well over 100,000 people who we claimed as kin. I have the tree on ancestry.com. Anyone who subscribes to Ancestry and is interested in their ancestors from Swain, Graham, Clay, Cherokee, Transylvania, Jackson or Haywood Counties in North Carolina might just find something there. The tree is named ABCDS. I can also be contacted by email at eaammons@charter.net

I’m coming at this a day late; spent yesterday working on the cemetery grounds and was too whupped to post last night. I just wanted to say that while there is much on Ancestry.com that you have to beware of in terms of misinformation, Ed’s ABCDS tree is top notch; he almost always includes supporting documentation. He failed to note that in addition to establishing and documenting all of the connections, he has invested a great deal of effort into transcribing and posting obituaries. For those doing genealogical work, those obituaries are wonderful resources. Thanks, Ed, for all that you do.

That seems like a long and and complex process but the results are worth it!

I really enjoyed reading Bill’s story. I had no idea what all was involved in making molasses. I am learning so much more than I ever thought I knew from your post and from your YouTube channel about Appalachia heritage. Thank you for sharing!

Gosh Tipper, this post brought back so many memories. I remember the molasses, boy was it good on a biscuit. When you were talking about putting potatoes in the hot coals, we did that. I loved that memory. It was alot of hard work, but we sure did manage. Wow! I just went down memory lane. Love it. Thanks.

yesterday post. Ron you got that right and after I thought about it for awhile I realized dad said {cloudy} all around and pouring down the middle

Only think of making Maple SYRUP… ancestors that settled here in SW Ohio In early 1800’s did make molasses. What a huge job!

Before Covid, I use to go buy molasses from a church in Avery county NC every fall. But with things as they are they’re not holding their event anymore. Wonder if this will be another mountain tradition that fades away.

The sorghum Bill describes was slow good. Some folks, I understand, have traded the mule for a 4-wheeler. I recall Dad growing sorghum cane at least one year but for the life of me I can’t remember what we did with it. We did not have a mill or cooker or anything. But I do recall he looked sorghum, but only “good” sorghum – by his lights anyway. My experience is too narrow to have formed a refined udgment.

On another subject, we listened to Mountain Path chapters 3 & 4 this AM. I will send you a picture from that country here by and by that I think you will appreciate. For here and now though I’ll just say again Ms. Arnow really got it right and you are the perfect one to read it because you both love it and understand it ‘behind the scenes’ as it were. You know the folkways that makes the characters act as they do. I dearly hope when you have read it all it gets into a consolidated audiobook.

Sorry folks. Dad “loved” (not looked) sorghum.

A family about a mile down the road used to have a big molasses making party every year. Their papaw and daddy have both passed away and the syrup making came to an end. I never knew so much work went into making the syrup until I read Bill’s description. I paid $9 for an 8 ounce jar of homemade sorghum from a farmer who sells his Kentucky Proud goodies at a country store and it was worth it.

I assume you’re discussing sorghum which isn’t a thing as far as I know here in WV. I had a friend from Starr, SC who’s job it was to give out sorghum to the folks in employment when he was a boy. Each got only so much and there were to be no extras for the sad sap story tellers. He said they could tell some whoppers too. But he grew to be a hard businessman partly from the experience.

Tipper–This was a bittersweet treat for me. I absolutely love Bill’s excellent description of the process involved in making sorghum syrup, but reading this reminds of just how much I miss Bill. He was a full to overflowing repository of mountain knowledge and lore as well as someone whose friendship I cherished.

All of the family operations of sorghum making that I knew of in E.Ky. are gone. What has taken their place is sorghum festivals, just ain’t the same. Dad took us every fall to an old friend’s mill but we didn’t have to do all the work Bill did. Our work was only to strip the blades from the sorghum cane in the field. Later we would cut a short piece of cane and swirl it around in the cooking syrup, delicious. After licking that off you go in for another dip. Don’t try that at a sorghum festival You know covid couldn’t even survive in that boiling syrup.

Yeah, I do miss the old days and the old ways.

I enjoyed reading Bill Burnett’s memories. When I lived in Iowa I had two huge sugar maples in my front yard. I always wondered if they had been planted when my house was built in 1890. I loved seeing the buckets catching the syrup on the trees around the area I lived in there. It made me feel connected to a way of life I always wished this Southern California raised girl had grown up in. I think I will make pancakes this morning, I am now craving real maple syrup. Molasses cookies sound like something I might make this afternoon, too. You always give me so many wonderful ideas for meals and snacks! I probably should set up a stand of free food down the hill at the end of my driveway – just so I can feed someone all the food I want to make after visiting with your blog and channel!

Donna. : )

I remember many mills in the area late 40’s and ’50’s….watching an old mule patiently walking around in a circle..my neighbor, the Seabolts make sorghum so does the Hughes family in Young Harris….family tradition for both families..